2016 Ringier Technology Innovation Awards - Plastics

Year:

- Automation

- W8 Pro Robot

-

The new pro series takes the WITTMANN W8 robot series to a whole new level of performance. – Countless improvements guarantee the highest efficiencies. -Rugged design of the robot. -Modularity of the robot mechanics and of the drive and control system architecture. -The elaborate modular WITTMANN robot design allows for an optimal cost/performance ratio. Advantages: – Reinforced profiles for higher load rating and longer durability. – ambiLED indicator lamp for simple display of the robot‘s operating modes. – EcoVacuum: synchonized vacuum for optimizing the consumption of pressurized air. – Minimized number of cables in the cable chain through innovative decentralized arrangement of the electronic components. – Reduced noise emission through optimized cable chain. – Integrated energy storage for higher energy efficiency, creating typical savings of 20%. – Integrated connection technology for vacuum and gripper circuits. Nike Sneakers

-

WITTMANN BATTENFELD (SHANGHAI) CO., LTD.

- Automation

- Striding Axial Robot

-

The best robot for two-platen injection molding machine,own large working area,effectively save the transverse space. Axial installation save a space more than 30% compared with traverse installation,accord with modern workshop management concept. Sneaker

-

NINGBO WELL-LIH ROBOTS TECHNOLOGY CO.LTD.

- Automation

- XTA-3000HDt Double Main Arm Manipulator

-

XTA-3000HDt manipulator is one of the super-large models, which can be installed on as large as 4500T IMM. The model is featured with large load, long stroke and double main arms. Simultaneous inserting of large plastic work piece in fixed and moving platens can be realized by the grippers of manipulator arm, as well as the picking out of plastic unit. Currently, XTA-3000HDt is mostly applied to automobile industry. Sneaker

-

Ningbo Haitian Drive Systems Co.,LTD.

- Automation

- KUKA KR CYBERTECH Nano Series

-

KR CYBERTECH nano is the first series in the new KR CYBERTECH robot generation which will boast the world’s largest model range in its class in the not-too distant future. Developed with an overarching objective: to offer you incomparable performance and power density in the payload category from 6 to 22 kg. At the highest level. As standard. With robot types perfectly tailored to your requirements for handling and path applications and, from 2016 onwards, with powerful robots for the broad spectrum of generic tasks in your production operations. Nike News

-

KUKA Robotics China Co.,Ltd.

- Auxiliary Equipment

- OTP – Optimized Temperature Pelletizing

-

The OTP process ensures a void free pellet production. Considering the physical parameter of a polymer, the thermal control scheme during pellet formation and conditioning must avoid internal tension generating. Temperature profiles for the cooling liquid (e.g. water) above atmospheric boiling point require therefore pressurized systems. The equipment is operating continuously and stable, including an integrated depressurizing step. Pellets produced by such a thermal controlled process are less brittle and generate less dust. The absence of voids is ensuring cleaner products with very low impurity level, a basic requirement for polymers used in optical applications or several electrical and other technical applications. Sneaker Release Dates 2019

-

Maag-Automatik Plastic Machinery (Shanghai) Co.,Ltd.

- Auxiliary Equipment

- VBD Vacuum Dryer

-

Maguire Vacuum Dryers are proven to dry all types of polymers in a fraction of the time and with up to 85% less energy than desiccant dryers. - Improved design obsoletes moving canisters and minimizes moving parts. - Continuous batch drying process. - -40° dew point air is constantly bled into vacuum and retention hoppers. - Vertical design minimizes footprint. - No heat loss is guaranteed with double-insulation on all vessels. - Reduced Maintenance - no desiccant to change - no filters to clean. - "No stress" material drying - means no material degradation. - Process temperatures up to 350°F. (175°C) - 5-year warranty Air Max 90 Ultra BR

-

Maguire Products Shanghai Co., Ltd.

- Extrusion & Blow Molding

- STS 75 Mc11 Twin Screw Extruder

-

With its specific torque of 11.3 Nm/cm3 the STS Mc11 sets new standards: it features up to 27% higher throughput rates than the preceding model, while the higher degree of screw fill results in a decrease of melt temperature, thus improving compound quality. It incorporates the full process and quality know-how of Coperion. The new STS Mc11 series is exclusively equipped with European, Coperion branded gearboxes. Maximum screw speed has been increased from 800 to 900 rpm. To improve cleaning and facilitate quick changovers for masterbatch applications, the STS also features new hoppers with inserts and a redesigned die head. The screw shaft coupling is similar to the one long proven in the ZSK Mc18 series. The new, optimized base frame withstands torsion under maximum stress. The STS Mc11 series covers most standard applications in process technology. It offers high productivity at an attractive price-performance ratio. Production of the STS Mc11 is in Nanjing, China, in compliance with CE directives. The result: A high-performance compounding system with low investment costs which ensures a fast return on investment. The modular design of the process section allows maximum flexibility in production at process lengths of 24 to 68 D. Nike Zoom Kobe Shoes

-

Coperion (Nanjing) Machinery Co., Ltd.

- Extrusion & Blow Molding

- Classicx Multi-layer Co-extrusion Blown Film Machine - Customized Solution/High Efficiency

-

Jinming Classicx blown film machine is a customized and high-capacity middle and high-end model which has been launched through the optimization of existing machine models. This model can meet the customer’s high production requirements in terms of film uniformity control, film transparency, film stiffness and toughness, film yield, etc. Based on standard configuration, Classicx models can be customized according to the actual production requirements and process conditions of customers. For Jinming Classicx models, the currently-available non-barrier blown film machines are applicable to both 3-layer and 5-layer films, whose width can vary from 1200mm to 3000mm. Application of intelligent control technology to improve the production & management technology and minimize the manpower. Lastest coextrusion and cooling technology increase the production capacity by more than 40%. Advanced machining center and European components ensure the stability of equipment operation. Extensive technical formula database and simulation system exercise to ensure higher film quality. Modular design of equipment to achieve flexible customization according to the requirements of customers. Extensive adaptability of film processing to meet the production requirement of high quality film. Nike Air max Dominate

-

Jinming Machinery (Guangdong) Co., Ltd.

- Extrusion & Blow Molding

- HDPE Three Layer Pipe Extrusion Line

-

In recent years, the large-diameter pipe extrusion line, especially in the large-diameter multi-layers composite pipe extrusion equipment is the weakness design in domestic plastic extrusion market, lower capacity, high energy consumption, low automationcontrol system and accuracy, complex operation the main case was the perfect pipe in low and not bring high profit for all customers,At the same time ,the energy saving policy discrepancy.Thus, the NEW market required low-power, high-capacity, high precisioncontrolled, easy to operation, intelligent controlled of the large diameter multi-layerscomposite polyethylene pipe extrusion line tothe domestic demand for pipe supplier Plant urgently. In view of the above circumstances, BEIER Machinery organized R & D personnel conducted an investigation both of the national and international markets, to learn the international advanced extrusion on the basis of further innovation and integration advantages of national products, incorporated with the design and development of scientific and technical for many years experience, successfully developed large caliber intelligent multi-layer polyethylene pipe production line. And access: invention patent (No. 2012101859352), utility model patents 7 (No.:2010205699768,2011202026737, 2010205719193,2010205699908,2011202026845,2010205699698、2010205699630). All the completed extrusion line controlledby PLC, Worker to Machine interface dialogue, to achieved the main extruder ,co-extruder, and haul off in synchronous speed, thus, the operation is extremely simple design. For example, as long as the pipe weight per meter input PLC panel, then transferred to the main extruder to desired speeddirectly, and the co-extruder and haul off will appropriated the speed up to the requirements of gravimetric meter automatically This operation extremely simple as true called "stupid machine." Truly large-diameter polyethylene pipe multilayer intelligent control. This extrusion line was tested by theTesting Center of Jiangsu Prov.China , All seized indicators in the extrusion line with corporate standards (Without industry standards or national standards in China) requirements specified Q / 320582BRJ16-2015; the novelty search organization by national level - Science Technology Advisory inquiry Center,Jiangsu ,No found same extrusion design in the Chinese market. This extrusion line was approved by the identification of new products of Machinery Industry Association of Jiangsu Provinceon 4th.Dec, 2015 , All identified experts unanimously agreed the new extrusion design is the leading national level in China. Air Jordan VII 7.5 Ture Flight

-

Beier Machinery Group

- Extrusion & Blow Molding

- Steel Reinforced Corrugated Pipe Production Line

-

Large diameter steel reinforced polyethylene corrugated pipe is developed by Goldstone based on the normal polyethylene spiral corrugated pipe. The pipe is researched by Goldstone independently and owned the patents for the pipe also the making machine. Reinforced by high strength steel belt, and a special material and coating is applied to give the solution of steel anti-corrosive. The diameter of the pipe is from 300 mm(12inch) to 3200 mm(126inch). The obvious advantage of the new composite pipe is the high stiffness and low cost if compared with the universal buried plastic sewage pipe. The ring stiffness reached SN8(63PSI) to SN16(126PSI), which is a surprise value for other plastic pipes. This pipe meets ASTM 2435-12 standard and Israel, Italian standard, Chinese national standard etc, and widely used in Beijing Olympics, Sochi Winter Olympics etc. Alphabounce Instinct

-

Sichuan Goldstone-Orient New Material Equipment Inc.

- Injection Molding

- Haitian JUIIS Series Two Platen Injection Molding Machine

-

-

Haitian Plastics Machinery Group Co.,Ltd.

- Injection Molding

- Adaptive Process Control (APC)

-

The newly developed APC machine function from KraussMaffei immediately compensates for fluctuations in the injection molding manufacturing process. Processors will benefit from a uniformly high component quality, lower scrap and material costs and the simplified use of recyclate. Furthermore, the implementation of APC increases energy efficiency in injection molding production. APC is offered for all series from KraussMaffei. Men Shoes - Football

-

KraussMaffei Technologies GmbH

- Injection Molding

- Systec 210-430

-

Less weight, more functions, attractive appearance –a lightweight nutcracker, which is then systematically reinforced by UD tapes a complex production method. The finished product with better functionality weighs 35 % less than its predecessor. The partners involved in this brand new development, which was never shown before in this specific combination, were automation specialist M.A.i GmbH & Co. KG of Kronach/Germany, decorative foil specialist Leonhard Kurz Stiftung & Co. KGof Fürth/Germany and plastics processor HBW-GubeschGmbH of Emskirchen/Germany. Release Calendar

-

Demag Plastics Machinery (Ningbo) Co.,Ltd.

- Injection Molding

- iQ Weight Control – With Correction of Holding Pressure

-

To achieve producing moulded parts of a consistently high quality shot by shot,the iQ weight control software analyses the pressure profile at the screw position in real time during the injection process and compares the measured values with a reference cycle online. Based on these results, the switchover point and the injection profile are adapted to the current conditions which keeps the injected volume constant during the entire production run. Thus the effects of fluctuations in viscosity on the filling of the mould, especially in applications with switchover points that depend on the injection pressure, can also be compensated. Mercurial Superfly Heritage FG

-

Engel Machinery (Shanghai) Co., Ltd.

- Injection Molding

- DH2000J1370 Injection Molding Machine

-

DH2000J1370 plastic injection molding machine is designed and developed large two platen clamping structure of the injection molding machine products by tederic independent.After the development, debugging and feedback many times, we continue to make improvement. It has now been successfully applied to large volume injection, large deep cavity products production. Adidas

-

Tederic Machinery Co.,Ltd.

- Key Component

- CRM-HMA420 Cam-Ring Piston Hydraulic Motor

-

This is a new type of compact structure motor with the outstanding performance. The CRM - HMA420 can provide all the advantages of the radial piston motors, and realize the double facing distribution. The displacement can be up to 26L,the max torque more than 100000 N.m, to realize large torque output with simpler structure, more efficient, more stable performance, and higher cost performance. Women's Fashion

-

STF Hydraulic Transmissions Co.,Ltd.

- Key Component

- Honeycomb Type Magnetic Steel Template

-

Electric control permanent magnet quick die change system is to use an electrical pulse on and off of the new magnetic mold clamping systems, magnetic materials with different characteristics optimum magnetic circuit design, by the electronic control system for the distribution of internal magnetic field lines can be controlled with a magnetic field conversion, so that the magnetic field is superimposed system to achieve internal balance,characterized as the external degaussing (DEMAG) that is relaxed state; or released into the working surface of the mold, characterized as the external magnetization (MAG) that is sandwiched state. Nike Hypervenom Phantom II FG Low

-

Hunan Qianhao Electrical and Mechanical Technology Development Co., Ltd.

- Measurement & Inspection

- Primus+

-

Sesotec standard control unit for plastics industry with 15% more sensitivity compared to the previous model PRIMUS, intuitive operation with LC graphic display and clear buttons arrangement, function „Auto-Set“ for optimum compensation of product effects and other influencing factors on-site (e.g. product effect, vibrations or electro smog) , maximum interference immunity due to state-of-the-art DSP technology, integrated logbook for up to 100 entries, and memory for 10 different products. Jordan sneakers

-

Sesotec China Co.,Ltd.

- Measurement & Inspection

- Datacolor 800-Benchtop Spectrophotometers

-

The Datacolor 800 Family of Benchtop Spectrophotometers, with its new embedded processor and data storage, provides a platform for increased efficiency and color measurement confidence, while delivering Datacolor’s best-in-class precision, accuracy and fleet compatibility. Air Max 95 20th Anniversary

-

Datacolor Trading (Shanghai) Co.,LTD.

- Molds & Components

- EVA Photovoltaic Automatic Film Die and Feedblock

-

·The thickness precision and continuous stability of the product improve ·It can be increased from ±5% when uesd the original manual mode to ±2% ·It can reduce the operating labor cost ·It can improve 50% in the speed of the production line EVA automatic die with the swinging blade distributor can achieve technical progress in multilayer coextrusion technology and performance upgrade etc. Air Jordans

-

Zhejiang Jingcheng Mold Machinery Co.,Ltd.

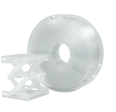

- Other Innovative Products/Technologies

- 3D Printing Filament for Fused Filament Fabrication

-

Polycarbonate, with its excellent property in heat resistance, transparency and gloss surface. It’s the most widely used engineering thermoplastics in the world. Covestro (formerly Bayer MaterialScience), advanced chemical materials developers and Polymaker, 3D printing materials manufacturer located in Shanghai, co-develop a new line of Polycarbonate-based 3D printing materials with market-leading engineering and functional properties, specifically for the desktop 3D printer. The product gives industrial product more freedom, and can create a variety of complex design, which can be used as final product. Nike LunarEpic Low Flyknit

-

Covestro (Shanghai) Management Company

- Other Innovative Products/Technologies

- Unidirectional Glass Fiber CFRT Production Line

-

Unidirectional glass fiber CFRT production line is a procession of glass fibre & PP resin composite sheet production line. Glass fibre put into the melting PP resin inside the mould and then go through the three-roll calender for cooling and shaping into final product, thickness of final product is adjustable, finally go into stress relieving device . PP glass fiber board with this equipment , has high rigidity, high heat resistance ability, well flatness, flame-retarded, excellent physical properties can be substituted in many applications of engineering plastics, has very excellent application value. Nike Jordan Super Fly 5

-

ZHANGJIAGANG DIDA Machinery Co., Ltd.

- Other Innovative Products/Technologies

- Freeformer

-

-

ARBURG

- Plastics Raw Materials & Additives

- Diacetyl Epoxidized Vegetable-Oleic Acid Glyceride

-

After years of research, Hairma has invented a new plasticizer Two acetyl epoxidized vegetable oleic acid glyceride HM-828,based on vegetable oil with efficiency and safety characteristics.HM-828 takes soybean oil as raw material, through react of stoichiometry alcoholysis、esterification and acetylation to generate acetyl oleic acid glycerin ester; further, through epoxidation to generate two acetyl epoxidized vegetable oleic acid glyceride. As a new product of the upgrading of the epoxidized soybean oil,HM-828’s compatibility with PVC resin has significantly improved..HM-828 has been successfully applied for CAS number and has obtained two Chinese invention patents. Meanwhile, we are applying for two international invention patents of European Union and America. Furthermore, to be identified the achievements of scientific and technological by China Light Industry Association,the product has been awarded a certificate of identification, and the certificate number is Light United Kejian Zi [2015]No.011.Appraisal committee experts believe that the project of HM-828 has reached the international leading level. Max 90 Winter Sneakerboot

-

Hairma Chemical (GZ) Ltd.

- Plastics Raw Materials & Additives

- Scentless Pelletized Aluminum Pigment

-

Scentless Pettelized Aluminum pigment :first dried Aluminum paste in vacuum condition after it cleaned by environment-friendly scentless solvent, later add polyethylene wax (or other resins ) and additives into dried Aluminum pigments then extrude that into cylindrical object about 1.8*8mm by an extruder. And moreover ,contents of Pelletized Aluminum pigment are about 75% Aluminum , 20-30% polyethylene wax or resin and little additives. Air Zoom Pegasus 34 Leather

-

ANHUI SUNRISE ALUMINIUM PIGMENTS CO.,LTD.

- Plastics Raw Materials & Additives

- Fragrance Master Batch

-

PolyOne can customize fragrance Master batch to meet consumers’ needs, whatever the smells of fruits, flowers or even specific request. Above pictures are bottles & Caps for skin care, hair care, house hold etc. The fragrance MB satisfies consumers to experience favorite smell, the “smell catching” helps brand owners differentiate products from others which same as “eye catching”. And avoid the spread of bacteria due to no need to open caps & closures to smell the contents inside, since fragrance MB helps consumers learn products typical smells already. Jordan

-

PolyOne

- Plastics Raw Materials & Additives

- New PMMA Alloy

-

M1600 possesses high toughness,paint-free. It is of black and high gloss and can meet exterior weather resistant requirement of 2500KJ/m2. Compared to painted products, costs can be decreased by 40% and more environmental friendly by using M1600 in molding. M1600 has been evaluated by several OEMs. Nike

-

Shanghai Kumhosunny Plastic Co.,Ltd.

- Plastics Raw Materials & Additives

- INNATE™ Precision Packaging Resins

-

INNATE™ Precision Packaging Resins are a new family of innovative resins that address some of today’s more challenging packaging performance gaps with an unprecedented balance of toughness and stiffness in combination with excellent tear and puncture resistance. Created from a patented molecular catalyst coupled with advanced process technology, INNATE™ will empower customers to unlock new packaging opportunities through unmatched stiffness-toughness balance, processing ease and improved sustainability profiles. Co-extruded film made with INNATE™ resins offer up to twice the abuse resistance of standard materials currently available in the marketplace. This family of resins is born from breakthrough process technology that allows accurate and consistent control of the resin chemistry for marrying film properties like never before. Air Foamposite One Pro

-

Dow Chemical Pacific (Singapore) Pte Ltd.

- Plastics Raw Materials & Additives

- New polyamide 6 for the Inner Liners of Automotive High-Pressure Natural Gas Tanks

-

Ultra-strong, lightweight and excellent barrier effect against natural gas LANXESS has developed a new high-tech Durethan® polyamide 6 grade that is ultra-tough at extremely low temperatures. It can be used to manufacture tanks that are lighter and more cost-effective for natural gas-powered cars. A tank system based on the new material has already proven itself to be ready for series production.Ultra-strong, lightweight and excellent barrier effect against natural gas LANXESS has developed a new high-tech Durethan® polyamide 6 grade that is ultra-tough at extremely low temperatures. It can be used to manufacture tanks that are lighter and more cost-effective for natural gas-powered cars. A tank system based on the new material has already proven itself to be ready for series production. Apparel

-

LANXESS Chemical (China) Co., Ltd.

- Plastics Raw Materials & Additives

- Borstar® RA140E Hot & Cold Water Pipe

-

Borstar® RA140E is a hot and cold pipes designed for plumbing, heating and transportation of water supply to modern homes and commericals. RA140E is a tri-modal PP-R material which makes it unique from standard PP-R. It is produced by linking three reactors in series and combining state-of-the-art alpha nucleation technology. This enables the material to be engineered into a structure providing an optimum balance between processability and mechanical properties. The below table demonstrates the differences in performance properties of RA140E and standard PP-R material. Air Jordan II High

-

Borouge

- Plastics Raw Materials & Additives

- Eco-friendly LED Material-Light Diffusing PP

-

A new material can transform LED lots or lines source into lines or planes light source. The product can address the issue that strong visual impact brought by LED light source. Plus, in the premise of high light transmittance, it can soften the light. This product can be obtained by simply injection molding and can be cut freely. Besides this, it can greatly improve production efficiency compared with traditional frosted glass. Kobe AD EP Shoes

-

Shanghai Sunny Technology Co., Ltd.

- Recycling Machinery (New)

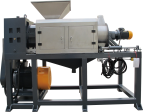

- SQUEEZR & AGGREGATER

-

Squeezing agglomerator will take process for the film or woven bags which are washed and clean by squeezing and drying. With the help of squeezing agglomerator, it solves the dewatering problem or feeding problem for the film after being washed. Comparing with previous type squeezer, current squeezing agglomerator with the unique principle about squeezing solve the difficulties about dewatering for the film or filiform plastic, what's more it could control the output humidity could be within 2%, and it is Less energy consumption and high degree of automation. Nike Air Jordan 11Lab4 Retro 4 Patent Leather

-

GUANGZHOU 3E MACHINERY CO.,LTD.

- Recycling Machinery (New)

- AUTOSORT FLAKE System

-

The AUTOSORT FLAKE system, from TOMRA Sorting Recycling (TSR), represents the ‘state of the art’ in advanced automated waste sorting and recycling. It is an extremely versatile machine, capable of the simultaneous sorting of three waste streams, and, notably, the sorting of both metals and colored materials, including non-transparent colored materials. The main application for the AUTOSORT FLAKE is the sorting of recycled polyester (rPET) flakes, but other applications include sorting PE/PP, E-scrap, and PVC flakes. The AUTOSORT FLAKE can be used in combination with the AUTOSORT to provide a complete PET bottles-to-flakes solution since between the AUTOSORT and AUTOSORT FLAKE the bottles undergo shredding and grinding. The flakes are then pre-treated, followed by sorting by the AUTOSORT FLAKE. SNEAKERS

-

TOMRA Sorting Recycling

- Recycling Machinery (New)

- IPS-1500 Intelligent Mixed Plastic Separation System

-

Armost IPS-1500 is designed and developed base on AES-1500 electrostatic separator and ARS-1000-V9 rubber separator, it is passed CE certification. Whole system has bigger capacity with high performance and specialize with Armost’s new design, it is the first full separation line to export to Europe. Nike Paul George PG1

-

Dongguan Armost Recycling-Tech. Co., Ltd.

- Rubber/Elastomer Materials and Additives (New)

- New Generation High Performance Sport Shoes Midsole Solution

-

The technology is based on Dow’s unique polyolefin products combined with Dow Elastomer’s break through formulation development. This technology provided a perfect solution for high performance midsole with superior advantage over the traditional midsole solution including lightweight (weight reduction by ~20%), high resiliency (better energy return by ~30%), comfort with good haptic (softness and rubber feel), better dimensional stability and durability (better compression set resistance), and thus could provide benefits across the whole value chain. Air Max 90 YEEZY 2 SP

-

Dow Chemical (China) Investment Co., Ltd.