2017 Ringier Technology Innovation Awards - Plastics

Year:

- Automation

- Electro-permanent Magnetic System for Quick Mold Change--Double Colored Injection Molding Machine

-

The Electro-permanent magnetic platen is used on standard injection molding machine and punching machine to clamp the mold or die. The clamping force is distributed evenly so that the lifetime of mold is extended and products are more consistent. The feature of the products is: keep the magnetic force without electricity for more than 30years; save electric energy by more than 95%; improve efficiency by more than 80%; environmental protection, no pollution; continuous upgrading, ect. Nike Air Penny 6

-

Qingdao Lici Electric Co.,Ltd.

- Automation

- Side Entry IML System for Twelve Cavities

-

The system can provide a technical solution for cambered label and multi-cavity( this mold is with12 cavites ). The principal axis is equipped with high-speed rotating motor, and functional structure operates synchronously in the mold zone. The dry cycle time is less than 1s. The upside-down top of label magazine solves perfectly the multi-cavity requirement, feeds labels very conveniently and reduce the probability of label falling-off. The interaction structures for picking label and product use the rotating rod structure, which motion is fast and stable. The whole system operate smooth and stable, and customers give approval and favorable comment. Air Force 1 High

-

Ningbo Well-lih Robots Technology Co.,Ltd.

- Auxiliary Equipment

- Smart PVC Hybrid Integrated System

-

Above the extrusion line feeding adopts accurate and flexible pipe chain proportion feeding solution,which can ensure the long distance flexible feeding of PVC compound above the extrusion line,what’s more,each pipeline can collect the production and status of downstream extruder to dynamically adjust the accurate feeding capacity of PVC compound,ensures accurate and even raw material supply, and it belongs to the first domestic flexible proportion feeding system. Air Jordan III 3 Shoes

-

Guangdong Liansu Machinery Manufacturing Co.,Ltd.

- Extrusion & Blow Molding

- Large Size Blow Molding Machine

-

To meet the needs of the market and more and more customers to recognize the blow molding products. We successfully developed a 20000L large-scale blow molding equipment, which is the first one in the world. We increased the capacity of the die head accumulator, customized larger size of the mold clamping plate. The electrical system of the machine maintain the original Siemens electrical parts, on this basis, which make the machine more efficient and smooth operation. Air Max 1 Ultra Essential

-

Qingdao Yankang Plastic Machinery Co.,Ltd.

- Extrusion & Blow Molding

- MSZ50 Injection Blow Molding Hi-Speed Machine

-

MSZ50 Injection Blow Molding Hi-Speed Machine, which we do the creative improvement on electric hydraulic system, electric control system, mold opening and closing mechanism, lifting mechanism. And achieve breakthroughs in speedy machine running and reduce action. Dry cycle time shortened from 3s to 1.8s. Compared with traditional hydraulic system, 30% to 40% energy saving is available. Electric control system increase the degree of automation as well as add much humanized design to make the machine user-friendly and convenient maintenance. Also production high capacity and ensure safety and reliability. Accessories

-

Jiangsu Victor Machinery Co.,Ltd.

- Extrusion & Blow Molding

- Full Electric Machine KBB Series

-

The all-electric KBB series sets new packaging standards not just in terms o the economy but also in terms of the operating convenience. • High speed: the dry cycle time of KBB20 series for small consumption packaging, is only 1.9 seconds, while the dry cycle time so KBB400 series for big industrial jerry cans, is only 4.8 seconds. • IntelliGate, modules for high-performance production: The IntelliGate system from Kautex turns your KBB blow molding machine into a complete production plant. The individual modules are coordinated to your machine by our experts and connected via the next generation Connext interface. This not only ensures that your KBB communicates to the individual modules, but also connects the compressed air and power supply to each module. With the Connext plug-and-play principle, you also achieve greater flexibility in your production. • Fast mold change system, significantly reduce downtimes: A change of product is often associated with loss of production time and risks. KBB machines are designed to reduce such downtimes. The patented Kautex fast-change system enables a mold to be changed in 15 minutes or less. In this system, every movement was analyzed by Kautex engineers in order to make handling not only fast but also as reliable and as safe as possible. • Easy handling: could be entirely operable and adjustable during operation; and retrieval of production data using a web interface on mobile devices. • Energy recovery system reach the aim of less energy: KBB series machine has the energy recovery system, which could recover the braking energy back to the machine or the electricity grid. Apparel

-

Foshan Shunde Kautex Plastics Technology Co.,Ltd.

- Extrusion & Blow Molding

- FLSJ60-40AG Series High-Efficiency Single Screw Extruder

-

FLSJ-G Series High-Efficiency Single Screw Extruder introduces most updated German technology. With its new design of barrier screw, groove barrel and spiral feeding section (with temperature control system), we ensures great adaptability to different materials and high-efficient & stable extrusion capacity. Modular computer control system, designed independently by Fangli, makes entire production line fully automatic. Through structural optimization and configuration enhancement, our line is not only with high output and high quality, also with prominent energy saving effect. Nike kyrie 2 Rainbow

-

Ningbo Fangli Technology Co.,Ltd.

- Extrusion & Blow Molding

- STS 35 Mc11 Twin Screw Extruder

-

With its specific torque of 11.3 Nm/cm3 the STS Mc11 sets new standards: it features up to 27% higher throughput rates than the preceding model, while the higher degree of screw fill results in a decrease of melt temperature, thus improving compound quality. It incorporates the full process and quality know-how of Coperion. The new STS Mc11 series is exclusively equipped with European, Coperion branded gearboxes. Maximum screw speed has been increased from 800 to 900 rpm. To improve cleaning and facilitate quick changovers for masterbatch applications, the STS also features new hoppers with inserts and a redesigned die head. The screw shaft coupling is similar to the one long proven in the ZSK Mc18 series. The new, optimized base frame withstands torsion under maximum stress. The STS Mc11 series covers most standard applications in process technology. It offers high productivity at an attractive price-performance ratio. Production of the STS Mc11 is in Nanjing, China, in compliance with CE directives. The result: A high-performance compounding system with low investment costs which ensures a fast return on investment. The modular design of the process section allows maximum flexibility in production at process lengths of 24 to 68 D. Adidas

-

Coperion (Nanjing) Machinery Co.,Ltd.

- Injection Molding

- DE Series Full-electric IMM

-

The DE series full-electric IMM, researched and developed independently by Tederic Machinery Co., Ltd., is applicable to medical, 3C, Packaging, Optical and Auto parts industry uses, meeting the demand of cleanliness strictly by some particular products and effectively controlling the possibility of pollution. They have already been put in operation in a number of electronics manufacturing enterprises, and raised peers' acclaims and clients' favor. Mercurial X Proximo

-

Tederic Machinery Co.,Ltd.

- Injection Molding

- HyperSync™ - Integrated System For Specialty Closures

-

HyperSync™ is the industry’s first fully integrated system for the manufacture of specialty closures, built to work together to provide synchronization, performance and speed. Husky is the industry’s first single-source supplier of integrated specialty closure injection molding machines, molds, hot runners, temperature controllers and productivity enhancement software. Guided by a system-level focus, our products are designed from the ground up to work together seamlessly. This integration provides the highest levels of control and performance possible, with an emphasis on product optimization and premium functionality of the parts. Nike Run

-

Husky Injection Molding Systems (Shanghai) Co.,Ltd.

- Injection Molding

- Two Platen Vertical Injection Molding Machine

-

First: Applied to an entirely new generation product of large vertical injection molding machine, fully humanized ultra-low workbench; The second: Equipment for two plate structure, reduce the mobile mechanism of the load from the weight, more convenient to do high speed running, shortened the time all sports; Third: in the aspect of mould schedule can be unlimited extension and shall not affect the work surface height, can break through the limits of conventional machines do travel, convenient different height of the mould; Adidas sneakers

-

Hangzhou TAYU Machinery Co.,Ltd.

- Injection Molding

- Haitian MAIIs Injection Molding Machine

-

Haitian MAIIs series servo injection molding machine is a product launched By Haitian after the comprehensive upgrading through the constant summary of customer demands and continuous self-improvement, and based on MAII series platform. By means of its new optimized design, Haitian MAIIs series servo injection molding machine is featured by more excellent dry cycle, reliability, stability and other performances. Adidas Shoes

-

Haitian Plastics Machinery Group Co.,Ltd.

- Injection Molding

- Volume Stretching and Plasticizing System

-

It is a kind of revolutionary plasticizing technology with global invention patent, cooperating with the academician team of Chinese Academy of Engineering of South China University, the application of new technology can greatly shorten the material thermal mechanical course, reduce the energy consumption, drop the size of the processing equipment, and it is a kind of new technology to processing polymer material which can save energy and drop consumption. With the volume stretching deformation processing forming method, it features high adaptability of material, short thermal mechanical course, good dispersing mixing effect and excellent product performance. Nike Business

-

Guangzhou UNIQUE Injection Molding System Co.,Ltd.

- Injection Molding

- Injection Molding Machine Industry 4.0 Solution-All Electric Injection Molding Machine Intelligent Flow Balancing Module

-

FCS develops “IMM industry 4.0 solution - All electric injection molding machine intelligent flow balancing module” which successfully solves the unbalanced flow problem from multi-cavity molding. It also helps to achieve an unattended factory and dramatically improve quality and competitiveness. NEW NIKE SHOES

-

FCS Group

- Injection Molding

- ENGEL e-motion 80 TL inject 4.0

-

inject 4.0 is ENGEL's answer to the challenges of Industry 4.0, the goal of which is smart factory. With the help of the networking of production systems, the systematic utilisation of process data, and the use of intelligent assistance systems, the manufacturing processes in a smart factory continuously optimise themselves and make it possible to react very flexibly to changing requirements. The results are higher efficiency, productivity and quality. To automatically compensate for fluctuations in environmental conditions and raw materials, the e-motion 80 TL inject 4.0 machine is equipped with three assistance systems: iQ weight control, iQ clamp control and iQ flow control. While iQ weight control keeps the injected melt volume consistent throughout the injection moulding process, iQ clamp control determines mould breathing in order to readjust clamping force continually. Finally, iQ flow control enables controlling the pump speed within the temperature control devices according to demand, thus saving energy. Nike Ambassador VIII 8

-

Engel Machinery (Shanghai) Co.,Ltd.

- Molds & Components (Including Hot Runner Technology)

- 7000mm Ultra-wide 3-layer Manifold Die

-

Our ultra-wide co-extrusion technology,which well meets with the special market requirements for ultra-wide barrier film used in waterproof and landfill, brings our users a brand new mode of production in high yield, high efficiency, low energy consumption and low labor cost.Meanwhile, it has promoted product performance and prolonged service life significantly. Air Jordan XXXI Low

-

Zhejiang Jingcheng Mold Machinery Co.,Ltd.

- Molds & Components (Including Hot Runner Technology)

- Summit™ Series Hot Runner System

-

Summit-Series is the new premium, no compromise brand of stainless steel hot runner designed for demanding Medical, Personal Care and Technical applications. Summit-Series is the ideal melt delivery solution for resins requiring the best in precise thermal control, corrosion resistance and chemical compatibility. adidas

-

Mold-Masters (Kunshan) Co.,Ltd.

- Other Innovative Products/Technologies

- Carbon-Fiber Products Intelligent Moulding Line

-

Carbon-Fiber Product Intelligent Moulding Line, which is produced and developed by Ningbo Shuangma Machinery Industry Co.,Ltd. is made for lightweight of automobile. CIML which is made of fiber convey structure, fiber mixing plasticizing structure and fiber production structure, is the LFT-D technology of single-stage processing producing with the composite material of long carbon fiber reinforced thermoplastic. The difference with long fiber granule injection technology is that there is no the process of granulator production, and it is more flexible in the material selection. The advantage of the CIML is that the final product has long fiber length, better performance and more cost-saving advantages. Besides, it could meet the final product requirement for Matrix polymer. It can change and influence the product’s mechanical performance and special material character by the additive dosage, such as heat stability, dye performance, UV stability and bond performance of fiber and Matrix. It means that the material recipe could be available for every special application by CIML. Zoom Lebron XV 15

-

Ningbo Shuangma Machinery Industry Co.,Ltd.

- Other Innovative Products/Technologies

- Form- Fill- and Seal Line Model FSL 48

-

With an ILLIG-FFS-Line, model FSL 48, that provides the whole process like forming, labeling, filling, sealing, and punching. ILLIG, Model FSL 48, gives you the following advantages: • High output with low maintenance effort. • High efficiency by optimized energy and material consumption. • High availability right from the start, fast and reliable commissioning. • High flexible labeling system, for brilliant decoration of your cups. • High quality of desinfection, for low acid products and longer shelf life. • High reliability, because of long lasting experiences. Nike kyrie 2 Rainbow

-

ILLIG Maschinenbau GmbH & Co. KG

- Other Innovative Products/Technologies

- High-speed Wide Permeable Film Production Line

-

The CPE permeable film production line manufactured by our company adopts once forming extrusion technique, the casting roller is driven by AC servo motor to regulate speed independently, each roller equips with independent water cooling speed regulating system, and it has flexible processing property. The production line can configure the combination of multi-drawing according to the actual needs of product performance. By adjusting the technical data of drawing machine, it can effectively adjust the air permeability and physical property of films,to achieve the higher performance. Mens Nike Cortez

-

Guangdong Liansu Machinery Manufacturing Co.,Ltd.

- Plastics Raw Materials & Additives

- Polyamide Material With High Resistance to Hydrostatic in the Field of Long-term Water Contact

-

The product has excellent mechanical properties, steady and high static pressure property, especially for tap water. It can maintain steady static pressure property and dimensional stability even contact with hot water. So it can be used on high pressure cleaning field such as water cannon, and washroom equipment instead of copper tee joint because of its environmental performance. Compared with metal product, it can realize one injection molding, improve design freedom and production efficiency, decrease production cost and carbon emission. NikeLab ACG.07.KMTR

-

Shanghai Sunny Technology Co.,Ltd.

- Plastics Raw Materials & Additives

- High Strength PC/ABS For Electroplating Handles—K8264

-

K8264 is a plating grade PC/ABS with high strength, excellent fatigue durability and good heat resistance. It was designed for high strength handles, and have overcame the bottleneck in formulation design of plating PC/ABS. The handles producted by this material can give a 30% higher strength to normal plating grade materials. So the safety of these handles was increased obviously. To now, it was used in several models, such as Chrysler 200C, Baojun 730, and so on. Nike SB Hyperfeel Koston 3

-

shanghai KUMHO-SUNNY Plastics CO.,LTD.

- Plastics Raw Materials & Additives

- Impress™ High Gloss Metallic Effect Colorants

-

Impress™ High Gloss Metallic Effect Colorants create a high gloss, metal effect look with no flow lines for polymer packaging, in a limitless range of vibrant colors. This technology enables packaging manufacturers to create unlimited combinations of color and gloss to design a brilliant metallic look that demands attention. Impress high gloss metallic effect color concentrates are formulated using an additive that adds a brilliant ultra-glossy appearance to packaging made with semi-crystalline polymers. The additive creates tiny bubbles inside the semi-crystalline resins which, when stretched during blow molding, reflect light and shine for a high gloss, metallic appearance. This technology is developed for PET solution, so benefit to “environmental friendly” in terms of recycle utilization. adidas Yeezy kaufen

-

PolyOne Corporation

- Plastics Raw Materials & Additives

- Body Insert

-

The "Body Insert" technology is LANXESS' injection molded insert made of reinforced fiberglass PA6, which significantly reduces the weight of a vehicle and improves passengers’ safety, compared to conventional metal automotive components. Metals such as steel and aluminum have high strength and hardness, while high-tech plastics such as glass fiber reinforced nylon can improve parts properties and reduce thickness. Compared with 100% steel parts, "Body Insert" technology has three major advantages: • Reduce weight by 50%; • Highly integrate functions of injection molding process and reduce processing steps to save cost by 40%; • Enhance precision, quality and strength. Footwear

-

LANXESS Chemical (China) Co.,Ltd.

- Plastics Raw Materials & Additives

- High Heat Resistant and Low Density Polypropylene Material for Portable Sockets

-

Based on phosphorus-nitrogen synergistic flame retardant mechanism and independent-developed catalytic-synergistic flame retardant technology, KINGFA developed a new flame retardant polypropylene material with high heat resistance and low specific gravity. The new material has satisfied the strict requirements of portable sockets, such as glow wire flammability index(960℃), ball pressure temperature(125℃), low temperature impact test(-20℃) and needle flame burning test(30s). The specific gravity of the material is extremely low and there is no antimony element in the formula. It also has many advantages, like short molding cycle, high thermal stability during processing, excellent long-term aging resistance and weathering resistance, etc. Nike

-

Kingfa Sci.&Tech. Co.,Ltd.

- Plastics Raw Materials & Additives

- HT-115K Efficient Environment-friendly Flame Retardant for PP Product Specification

-

HT-115K is a specialized environment-friendly flame retardant for Polypylenes, completely compliance with RoHs and REACH regulations. When loading a very small quanlity of HT-115K in Polypylenes systems can reach to UL94 V-2 (1-3%) or V-0 (7-8%), performs an excellent anti-yellowing,anti-migration,electrical and mechanicalproperties. Nike

-

Jinan Taixing Fine Chemicals Co.,Ltd.

- Plastics Raw Materials & Additives

- Enhanced EPE Foam

-

The enhanced expanded polyethylene (EPE) foam solutions from Dow Packaging and Specialty Plastics deliver high level of cushion performance and abuse resistance through Dow polyethylene resins and patented technology. With tailored LDPE/LLDPE blends and exceptional processability, this new foam solution achieves new levels of downweighting or downgauging. There is up to 15% savings on raw material cost in unit packaging while providing the same or better protective performance, this enables converters to have product differentiation and improve competitiveness in the industry. The reduction in thickness or weight allows more shipping space, improving the load-ability of containers. Brand owners and e-retailers receive less damages on goods delivered caused by packaging failure and consumers will enjoy a better protective packaging of high value goods. The compressive strength can be maintained at similar level after 20% downweight without sacrificing cushioning performance. This new foaming solution drives sustainable growth throughout the value chain and brings benefits to the stakeholders. Nike Jordan

-

Dow Chemical Pacific (Singapore) Pte Ltd

- Plastics Raw Materials & Additives

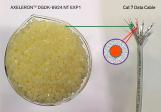

- AXELERONTM DGDK-6924 NT EXP1- Polyethylene Compound for Physically Foamed Insulation of High-end Data Cables

-

AXELERONTM DGDK-6924 NT EXP1 is a new generation polyethylene product used for physically foamed insulation for high-end data cables by Dow E&T, which provides superior advantage over the incumbent and competitive products, including high nucleating efficiency for much finer and more uniformly distributed cellular structure (30~45 micron meters), lower cable attenuation, faster production line speed (~1400m/min) and outstanding long-term aging performance. Air Max 90 YEEZY 2 SP

-

Dow Chemical (China) Investment Co.,Ltd.

- Plastics Raw Materials & Additives

- Environment Friendly Pelletized Aluminium Pigment

-

This series are processed by specific ball-milling technique and unique formulation, then to get pellets by extrusion. The main features: (1)Excellent generality; (2)Solvent free and pollution free; (3)FDA, PAHS, ROSH and REACHaprroved. Nike

-

Anhui Sunrise Aluminium Pigments Co.,Ltd.

- Plastics Raw Materials & Additives

- AEGIS® H55C2ZP PA6/66 Copolymer

-

AEGIS® H55C2ZP PA6/66 Copolymer has been designed to meet the growing needs for improved surface finish and improved toughness. H55C2ZP is a medium viscosity, neat resin allowing Custom Compounders and Injection Molders to meet challenging OEM specifications with low complexity and cost efficient formulations. Supplied Globally, H55C2ZP has achieved early success with adoption in the Engineering Plastics market including Automotive applications. Air Max 95 20th Anniversary

-

AdvanSix Materials Technology (Shanghai) Co.,Ltd. (Formerly Resins and Chemicals Division under Honeywell)

- Recycling Machinery & Components

- 6000KG/H PET Washing & Recycling Production Line

-

The thought of sustainable development is becoming more and more crucial. Beier Machinery specializes in PET Bottle washing and recycling solution which capacity ranges from 1000KG to 6000KG per hour, we can supply whole production solution like bottle to bottle , or bottle to fiber. through the process, the final plastic product can meet to food grade base on US standard. The 6000kg/h PET recycling line has the largest capacity in the industry worldwide .this is due to Beier Machinery latest technology development, the principle design method of this line is intelligent, automatic and labor free. we applied many intelligent components such as: auto bale open system, auto label remove, optical sorting and etc..., with those technology, Beier Machinery are able to supply the high capacity, stable, less labor need recycling solution for our clients. Air Max 1 Master

-

Jiangsu BEIER Machinery Co.,Ltd.

- Recycling Machinery & Components

- AES-1000 Multistage Intelligent Separation System for Mixed Plastics

-

AES-1000 multistage intelligent separation system, mainly focuses on the metal/nonmetal and different material of mixed plastics, adopting vertical integration design with the characteristics of high purity, low labor-cost, low power consumption, large capacity, safe and reliability, also reduces the floor area, shortens the transportation time, this system is the best choice for high efficiency and low cost. Nike Sneakers

-

Dongguan Armost Recycling-Tech. Co.,Ltd.