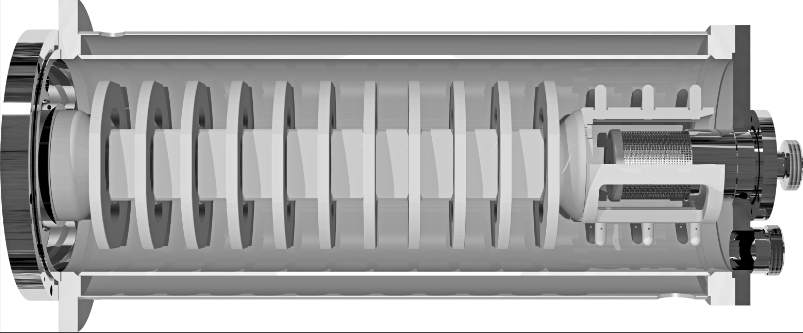

Based on a grinding disk geometry with additional activation elements and the use of wear-resistant ceramic materials with the highest thermal

conductivity, a significant increase in production output, averaging approx. 30%, had already been achieved for these agitator bead mills in 2012.

Now the grinding system has been modified again. For this new development, the main focus was on the grinding media separation and optimization

of the residence time distribution.

While in the original centrifugal separation system the entire process area was divided into a separation zone and a grinding zone, with the new

grinding media separation system the entire grinding area can now be filled with grinding media. This quite logically results in an increase in the

grinding capacity which corresponds to the grinding media fill volume.

Thumbnail (228 x 152 px):

Company:

NETZSCH (Shanghai) Machinery and Instruments Co., Ltd.

Innovation Awards:

2021 Ringier Technology Innovation Awards — Coatings Industry

Product Category:

Coatings Produce/ Test Equipment

Is Award Product?: